Firefighting remote control monitors

- Flow rate: from 500 to 8500 liters per minute at 7 bar

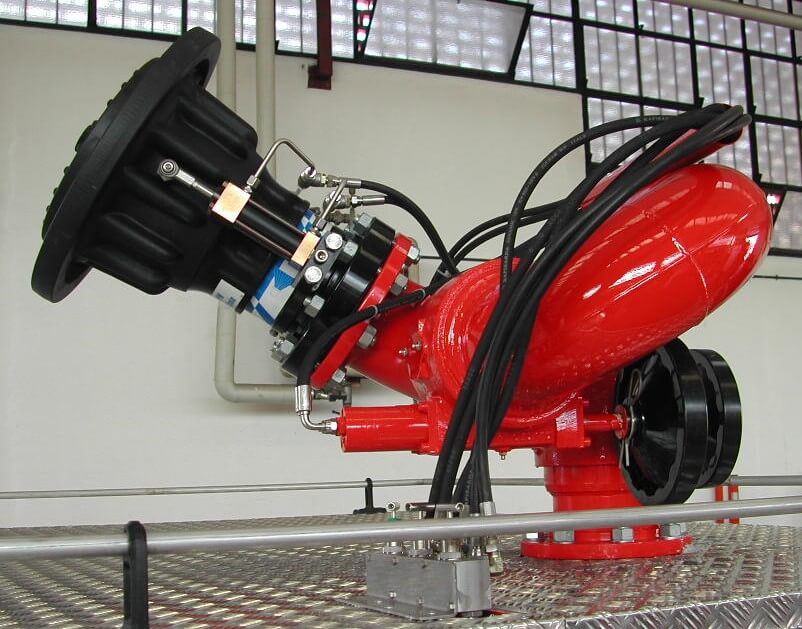

- Remote Hydraulic Oil Driven Monitors

- Remote Electro-Hydraulic Oil Driven Monitors

- Electrically Driven Bumper Monitors

- Turbine Driven Monitors hydraulic

- Radio-controlled monitors

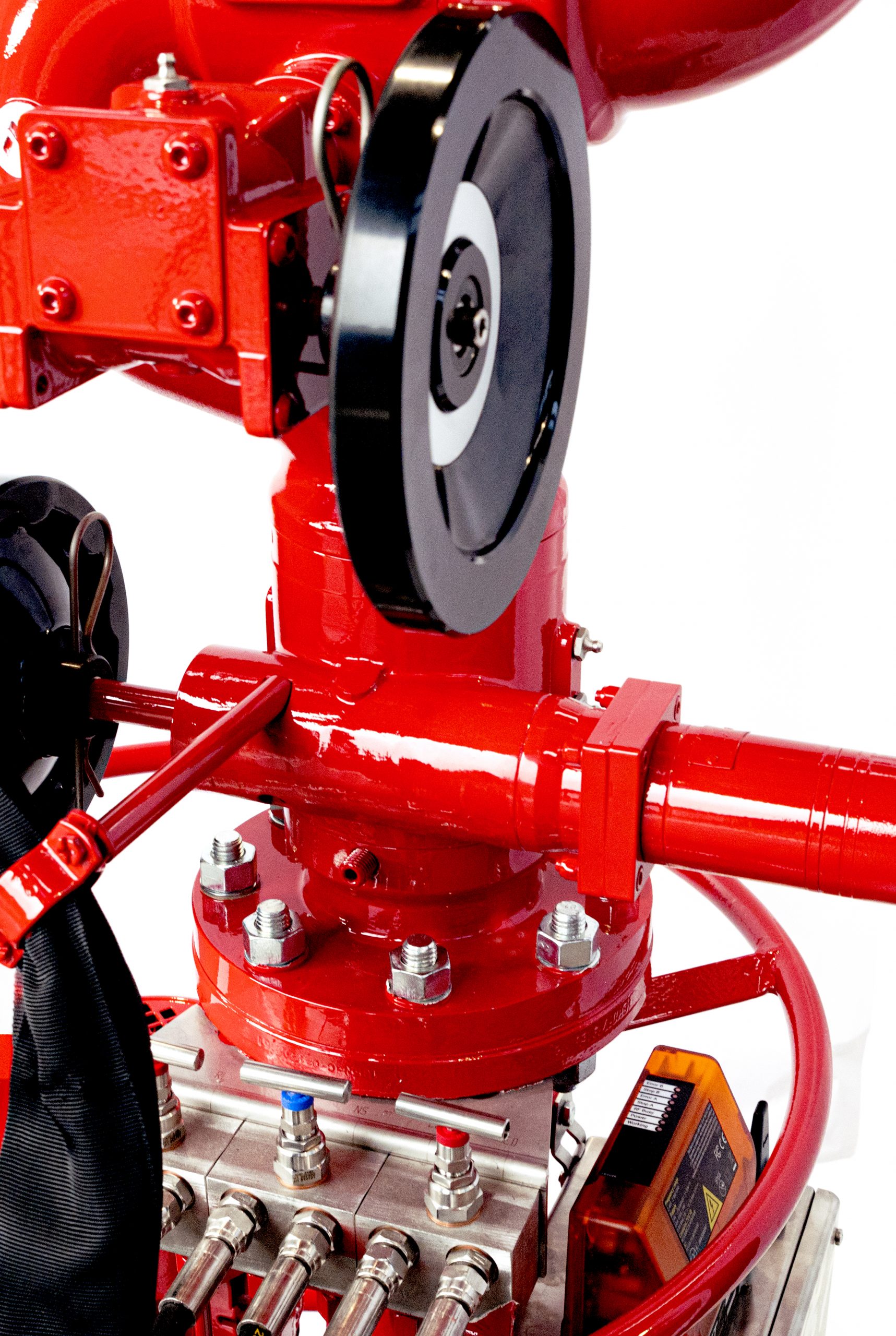

- Hydraulic power unit

- Hydraulic turbine unit with Pelton wheel

- Materials: brass, bronze, AISI 316

- ATEX certification: II 3 G C IIC T4, II 3 D C T130°C

- Operating pressure: 7 to 10 bar

- Series models Hudson

HUDSON Fire Monitor Range

MALECO offers a wide range of HUDSON series fire monitors, designed for use with water foam solutions for firefighting or as water for cooling civil structures and buildings. These monitors are suitable for a variety of applications in the civil, industrial, petrochemical, marine and vehicle mounted sectors, including fixed, mobile and portable fire engines. They can be operated with fresh water, sea water, dry chemical or water foam solution.

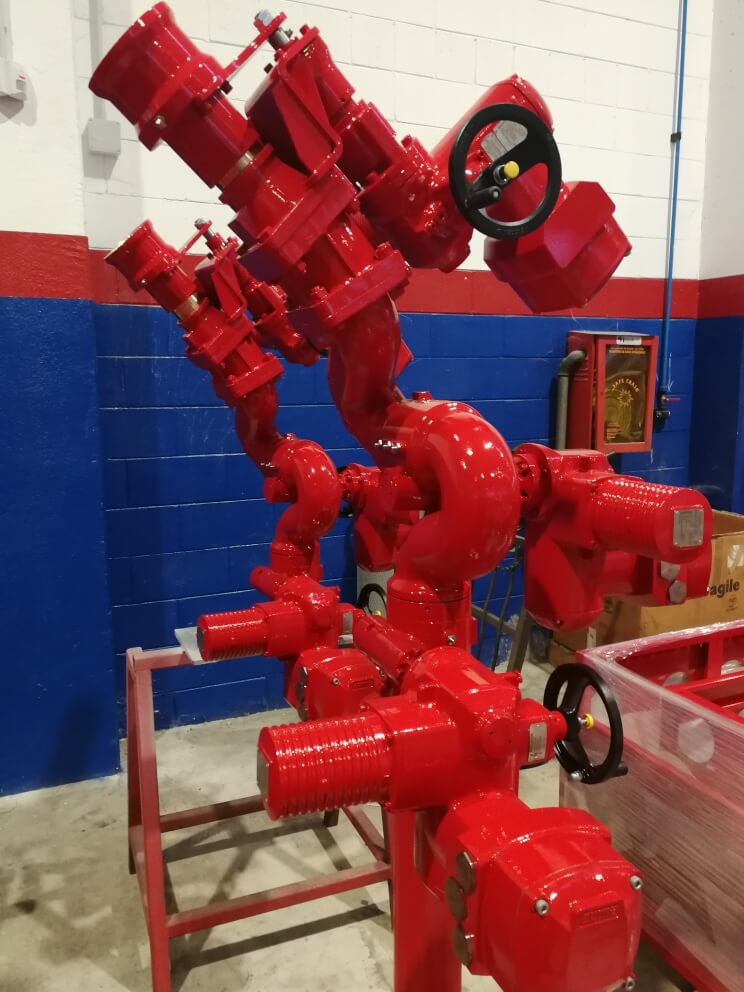

Hudson monitors are equipped with a wide range of jet/spray nozzles that allow the flow of water or foam to be adjusted from remote positions, from a straight jet to a wide spray pattern. They can be equipped with a wide range of stainless steel suction cannons or with self-cleaning branched foam tubes. All standard and self-cleaning cannons can be equipped with optional foam diffusers, made of light alloy with anti-corrosion treatment.

Design

MALECO's team of experienced engineers are available to customize the equipment to the specific requirements of the fire protection application. HUDSON monitors are available in base materials such as bronze and stainless steel. Flow rates range from 500 to 10,000 litres per minute, depending on the model selected.

The 'S' shaped body of HUDSON monitors is designed to balance the reaction force and facilitate connection to different outlets/delivery devices such as nozzles or self-aspirating air or foam hoses. This design makes them suitable for harsh industrial environments and offshore applications.

HUDSON monitors are available with different control types:

- HL (Hand Lever): Operable by hand lever

- CV (Hand Wheels): Operable by hand wheels

- TCO (Hydraulic Oil Remote Control): Operable by hydraulic oil remote control

- TCE (Electric Remote Control): Operable by electric remote control

- TEO (Electric/Hydraulic Remote Control): Operable by electro/hydraulic remote control

- TAO (Radio Control or Water Turbines): Operable by radio control or water turbines water

- TWA (Double Barrel with Two Extinguishing Agents): operable with double barrel for two extinguishing agents

Where to fit

HUDSON monitors are suitable for protecting a wide range of fire protection applications including:

- Fixed civil and industrial installations

- Fuel storage tanks

- Fixed and mobile installations on monitors

- Firefighting vehicles and fire brigade emergency response

- Applications on ships or outboard systems

- Heliports and hangar

- Hydrant protection nets

- Full fuel loading and unloading platforms and docks

- Refineries